Amine Blushing Causes And Prevention

Amine blushing is a common after-effect of epoxy cures. It creates greasy deposits that prevent varnishes and coatings from properly bonding.

Guardian Garage Floors, a renowned garage flooring contractor, discusses how amine blushing occurs and how to prevent it.

AN OVERVIEW OF AMINE BLUSHES

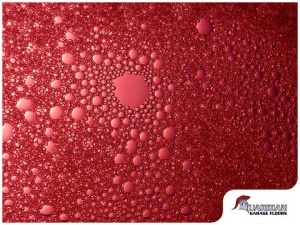

Amine blush occurs on the surface of cured epoxy. It has a greasy texture and appears like a thin, greasy or dull layer. Amine blushes are an issue when installing epoxy garage floors. The blush will prevent varnishing, epoxy coats and substrates from bonding. That said, it must be removed before applying any coating or varnish.

PREVENTION AND REMOVAL

Epoxy flooring will always create amine blushes unless you control the environmental temperatures. Keeping the garage between 60-80 degrees prevents condensation that causes the blushes. If amine blushing has already occurred, remove it before applying any new coating. You can spray soapy water and use a dishwashing pad to clean the affected surfaces. Then, wipe with paper towels to speed up drying.

THE BEST SOLUTION

Polyaspartic flooring is a special material that doesn’t create amine blushes. It’s also more durable and reliable than epoxy flooring.

Polyaspartic flooring is easy to install. It’s applicable in extreme temperatures, has good weather resistance and efficiently bonds with concrete. It cures clearly and won’t discolor or blush even if exposed to moisture.

There are other advantages of using polyaspartic coating on garage floors, such as its resistance to scratches, stains and chemicals. It also does not degrade when exposed to sunlight and can work with different curing agents.

Do you want an excellent garage floor that will last for decades? Turn to the experts at Guardian Garage Floors for the best solutions. Our team is ready to handle your garage floor needs. Call us at (615) 645-3696 or fill out this contact form for a free quote.